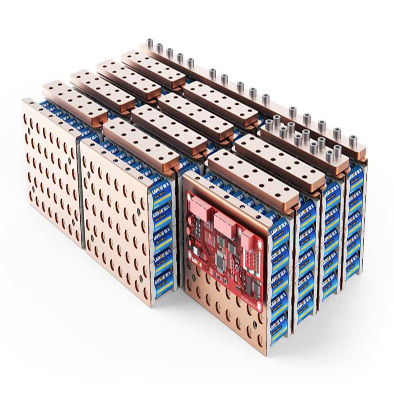

PRODUCT FEATURES

Details of LiFePO4

Lithium iron phosphate battery

Function and purpose

LiFePO4 electrode materials are mainly used in power lithium ion

batteries

Since NTT of Japan first exposed the olivine structure cathode material of

aympo4 (a is alkali metal, M is CoFe: lifecopo4) in 1996, John. B. goodenough

and other research groups of Texas State University in the United States also

reported the reversible migration of LiFePO4 into and out of lithium in 1997,

This material has attracted great attention, and caused extensive research and

rapid development. Compared with the traditional cathode materials for

lithium-ion secondary batteries, LiMn2O4 with spinel structure and LiCoO2 with

layered structure, limpo4 has a wider range of raw materials, lower price and no

environmental pollution.

Properties of LiFePO4

1. High energy density, the theoretical specific capacity is 170mAh / g,

and the actual specific capacity of the product can exceed 140mAh / g (0.2C, 25

° C);

2. Safety, it is the safest cathode material for lithium-ion battery at

present, and does not contain any harmful heavy metal elements;

3. Long life. Under the condition of 100% DOD, it can charge and discharge

more than 2000 times; (reason: the stability of LiFePO4 crystal lattice is good,

and the effect of lithium ion insertion and removal on the crystal lattice is

small, so it has good reversibility. The disadvantage is that the transmission

rate of electron and ion is poor, which is not suitable for high current

charging and discharging. Solution: coating conductive materials on the surface

of the electrode and doping to modify the electrode. )

4. No memory effect;

5. Charging performance: the lithium battery with LiFePO4 cathode material

can be charged at high rate, and the battery can be fully charged within 1 hour

at the fastest.

Specific physical parameters:

Lithium iron phosphate

Bulk density: 0.7g/cm

Compaction density: 1.3g/cm

The median diameter is 2 & shy; & shy; -- 4um

Specific surface area < 30m / g

Smear parameters:

LiFepo4:C:pVDF=90:3:7

Compaction density of electrode plate: 2.1-2.4g/cm

Electrochemical performance:

Test conditions: half cell, 0.1C, voltage 4.0-2.0v

1000 cycles

Novelty and characteristics

But its tap density is low, which affects the capacitance.

At present, the main production method is living method, and the product

index is unstable.

The performance of lithium-ion battery mainly depends on the positive and

negative electrode materials. Lithium iron phosphate as the cathode material of

lithium-ion battery only appeared in recent years. The development of large

capacity lithium iron phosphate battery in China was in July 2005. Its safety

performance and cycle life are incomparable with other materials, which are also

the most important technical indexes of power battery. The life of 1C charge

discharge cycle is 2000 times. Single battery overcharge voltage 30V does not

burn, puncture does not explode. Lithium iron phosphate cathode material is easy

to be used in series for large capacity lithium ion batteries. To meet the needs

of frequent charging and discharging of electric vehicles. It has the advantages

of non-toxic, pollution-free, good safety performance, wide source of raw

materials, low price and long service life. It is an ideal cathode material for

the new generation of lithium-ion batteries.

At present, lithium-ion batteries are mainly small capacity and low-power

batteries. Medium and large capacity and medium and high-power lithium-ion

batteries have not been produced on a large scale, so lithium-ion batteries have

not been widely used in medium and large capacity UPS, medium and large energy

storage batteries, electric tools and electric vehicles. One of the important

reasons is that the cathode materials for Li ion batteries have not yet made a

major breakthrough.

Cathode material is an important part of lithium ion battery.

So far, the most studied cathode materials are LiCoO2, LiNiO2, LiMn2O4 and

their derivatives, such as LiNi0.8Co0.2O2, lini1 / 3co1 / 3mn1 / 3O2, etc.

LiCoO2 is the only large-scale commercial cathode material. At present,

more than 90% of commercial lithium-ion batteries use LiCoO2 as cathode

material. The research of LiCoO2 is relatively mature, and its comprehensive

performance is excellent, but its price is expensive, its capacity is low, and

there are some security problems.

LiNiO2 has low cost and high capacity, but it is difficult to prepare. The

consistency and reproducibility of material properties are poor, and there are

serious safety problems. LiNi0.8Co0.2O2 can be regarded as the solid solution of

LiNiO2 and LiCoO2, which has the advantages of both LiNiO2 and LiCoO2. It was

once considered as the most likely new cathode material to replace LiCoO2.

However, there are still some shortcomings, such as harsh synthesis conditions

(oxygen atmosphere required), poor safety, etc., and the comprehensive

performance needs to be improved. At the same time, due to more expensive Co,

the cost is also higher.

Spinel LiMn2O4 has low cost and good safety, but poor cycling performance,

especially at high temperature, solubility in electrolyte and poor storage

performance.

The new ternary composite oxide lithium nickel cobalt manganate (lini1 /

3co1 / 3mn1 / 3O2) concentrates the respective advantages of LiCoO2, LiNiO2,

LiMn2O4 and other materials: the cost is equivalent to LiNi0.8Co0.2O2, the

reversible capacity is large, the structure is stable, the safety is good, it is

between LiNi0.8Co0.2O2 and LiMn2O4, the cycle performance is good, and the

synthesis is easy; but the cost is also high due to more expensive Co. The cost,

high temperature performance and safety of cathode materials are very important

for medium and high capacity and high power lithium-ion batteries.

The cathode materials of LiCoO2, LiNiO2, LiMn2O4 and their derivatives can

not meet the requirements. Therefore, the research and development of new

cathode materials for medium and high capacity and high power lithium-ion

batteries has become a hot spot.

LiFePO4 cathode material with orthorhombic olivine structure has gradually

become a new research hotspot at home and abroad. The preliminary study shows

that the new cathode material has the respective advantages of LiCoO2, LiNiO2,

LiMn2O4 and their derivatives: no precious elements, cheap raw materials,

abundant resources; moderate working voltage (3.4V); good platform

characteristics, extremely stable voltage (comparable with voltage stabilized

power supply); large theoretical capacity (170mAh / g); stable structure,

excellent safety performance (O and P) Strong covalent bond makes the material

difficult to decompose; high temperature performance and thermal stability are

obviously better than other known cathode materials; good cycling performance;

volume reduction when charging, good volume effect when cooperating with carbon

anode materials; good compatibility with most electrolyte systems, good storage

performance; non-toxic, it is a real green material.

Compared with LiCoO2, LiNiO2, LiMn2O4 and their derivatives, LiFePO4

cathode material has outstanding advantages in cost, high temperature

performance and safety, and is expected to become the preferred cathode material

for medium and high capacity, medium and high power lithium ion batteries.

The industrialization and popularization of this material is of great

significance to reduce the cost of lithium-ion batteries, improve battery

safety, expand the lithium-ion battery industry, and promote the large-scale and

high-power lithium-ion batteries. It will make the application of lithium-ion

batteries in medium and large capacity UPS, medium and large energy storage

batteries, electric tools, and electric vehicles a reality.

However, the disadvantage of low bulk density of LiFePO4 has been ignored

and avoided, which has not been solved, hindering the practical application of

the material. The theoretical density of lithium cobalt oxide is 5.1g/cm3, the

tap density of commercial lithium cobalt oxide is generally 2.0-2.4g/cm3, while

the theoretical density of lithium iron phosphate is only 3.6g/cm3, which is

much lower than that of lithium cobalt oxide.

In order to improve the electrical conductivity, the bulk density of carbon

doped LiFePO4 is significantly reduced by adding conductive carbon materials, so

that the tap density of carbon doped LiFePO4 is only 1.0-1.2g/cm3. Such a low

bulk density makes the volume specific capacity of LiFePO4 much lower than that

of licoo4, so the volume of the battery will be very large, which not only has

no advantage, but also is difficult to be used in practice.

Therefore, increasing the bulk density and volume specific capacity of

LiFePO4 is of decisive significance for the practical application of LiFePO4.

The particle morphology, particle size and distribution of powder materials

directly affect the bulk density of materials.

Based on the research results of high-density spherical Ni (OH) 2, we have

successfully developed a series of high-density spherical cathode materials for

lithium-ion batteries, including LiCoO2, limn2o4lini0.8co0.2o2, lini1 / 3co1 /

3mn1 / 3O2, etc.

Among them, the tap density of LiCoO2 and LiNi0.8Co0.2O2 can reach

2.9g/cm3, which is much higher than that of commercial similar materials.

Research and practical application show that spherical products not only have

the outstanding advantages of high bulk density and large volume specific

capacity, but also have excellent fluidity, dispersion and processability, which

are very conducive to the coating of cathode material slurry and electrode

sheet, and improve the quality of electrode sheet; in addition, compared with

irregular particles, regular spherical particles are easier to cover the surface

Therefore, spherical products are more hopeful to further improve the

comprehensive performance through surface modification.

At present, our laboratory uses divalent iron salt or trivalent iron salt,

phosphoric acid or phosphate, ammonia as raw materials to synthesize

high-density spherical iron phosphate precursor by controlled crystallization

technology, and then blends with lithium source and carbon source for heat

treatment to synthesize carbon doped spherical lithium iron phosphate by

carbothermal reduction method. The LiFePO4 powder material is composed of

monodisperse spherical particles with particle size of 5-10 μ m, high bulk

density (tap density of 1.6-1.8g / cm3), good fluidity, good processability and

reversible capacity of 140mAh / g.

Production technology of LiFePO4

1、 Project introduction: the performance of lithium-ion battery mainly

depends on the anode and cathode materials. Lithium iron phosphate as a lithium

battery material only appeared in recent years. The development of large

capacity lithium iron phosphate battery in China was in July 2005. Its safety

performance and cycle life are incomparable with other materials, which are also

the most important technical indexes of power battery. The life of 1C charge

discharge cycle is 2000 times. Single battery overcharge voltage 30V does not

burn, puncture does not explode. Lithium iron phosphate cathode material is easy

to be used in series for large capacity lithium ion batteries. To meet the needs

of frequent charging and discharging of electric vehicles. It has the advantages

of non-toxic, pollution-free, good safety performance, wide source of raw

materials, low price and long service life. It is an ideal cathode material for

the new generation of lithium-ion batteries.

2、 Technical features

The technology route uses iron phosphate and lithium carbonate as the main

raw materials, and has unique advanced reaction method to prepare lithium iron

phosphate with excellent conductivity.

(1) It avoids the problem of using ammonium dihydrogen phosphate as raw

material in other synthesis methods, which produces a lot of ammonia gas and

pollutes the environment.

(2) A special mixing method is adopted to make the additive fully mixed

with lithium source, iron source and phosphorus source, and directly calcined

without drying. In the subsequent reaction, the additives can not only play the

role of reduction, but also form the coating effect on LiFePO4 particles, which

can greatly improve the conductivity of cathode materials.

(3) This process uses dry mixing, no ethanol, no drying, reduce process

steps, reduce equipment investment, reduce costs, and increase the safety in the

production process.

(4) The process route adopted is easy to control, the process stability is

good, and the cost is low. The raw materials and equipment used are all from

home, which greatly reduces the cost of industrialization. Easy to achieve mass

production.

(5) The capacity per gram of LiFePO4 material developed by the new

technology has reached or exceeded that of imported products.

The average particle size is 2-4 μ M2-4 μ M2-4 μ M2-4 μ M

Specific capacity > 130 typ 135 > 130 typ 140 > 130 typ 135 130

typ 135

Tamping 1.51.11.21.5

Specific surface area (m2 / g) 12 < 15 < 15 < 20

Volume decay rate (%) < 10 < 20 < 15 < 15 after 2000

cycles

Technical quality index

Appearance: gray black powder, no caking.

Physical properties:

X-ray diffraction: compared with jcds standard, there is no impurity.

Particle size distribution: normal distribution, D50 = 2-3 μ m, D90 < 10

μ M.

Tap density: 1.5g/cm3.

Electrochemical performance: 1C discharge capacity > 130mah / g

2000 cycles, capacity attenuation less than 15

-

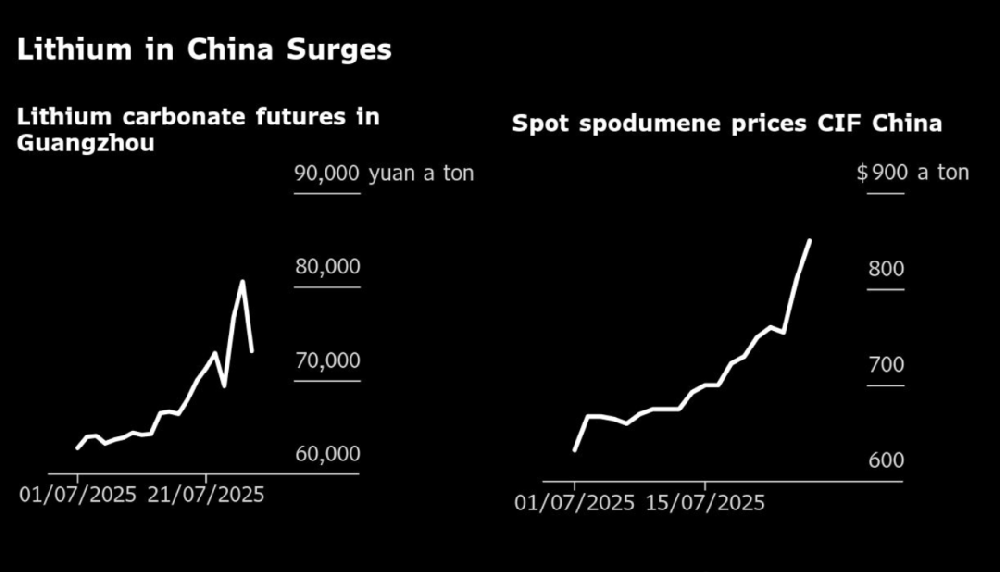

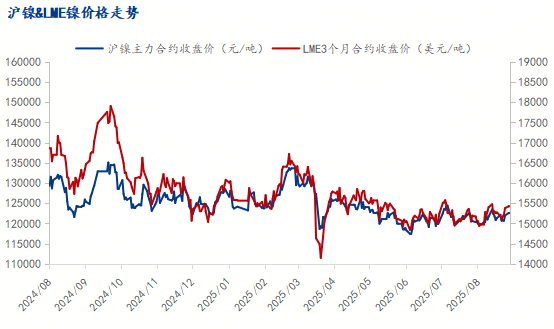

Nickel Market Update - October 28th

Oct,29,2025

-

Market Update on Nickel Prices in Nov.2025

Oct,29,2025

-

Oct,29,2025

-

Mid week analysis of cobalt lithium new energy market and prices in October 2025

Oct,29,2025